Digital manufacturing is revolutionizing the jewelry industry with a slew of technological advances. Now, jewelry designers have more freedom and room to be as imaginative and creative as they wish to be with their designs. If you’re curious about how these advancements have made the trade simpler, faster, and better, read on to learn how the jewelry manufacturing industry has changed and how digital manufacturing can help your jewelry business grow.

Digital Advances Save Time

Among the biggest ways that digital manufacturing helps today’s jewelers is cutting down on the time they spend on designing and creating. High-tech manufacturing allows for a quicker lead time, which in today’s fast-paced world, is crucial. It gives designers the opportunity to easily and quickly modify a design according to the customer’s needs. If a customer wishes for a slightly different design than the first proposal, the designer can use technology to make the changes in a matter of minutes.

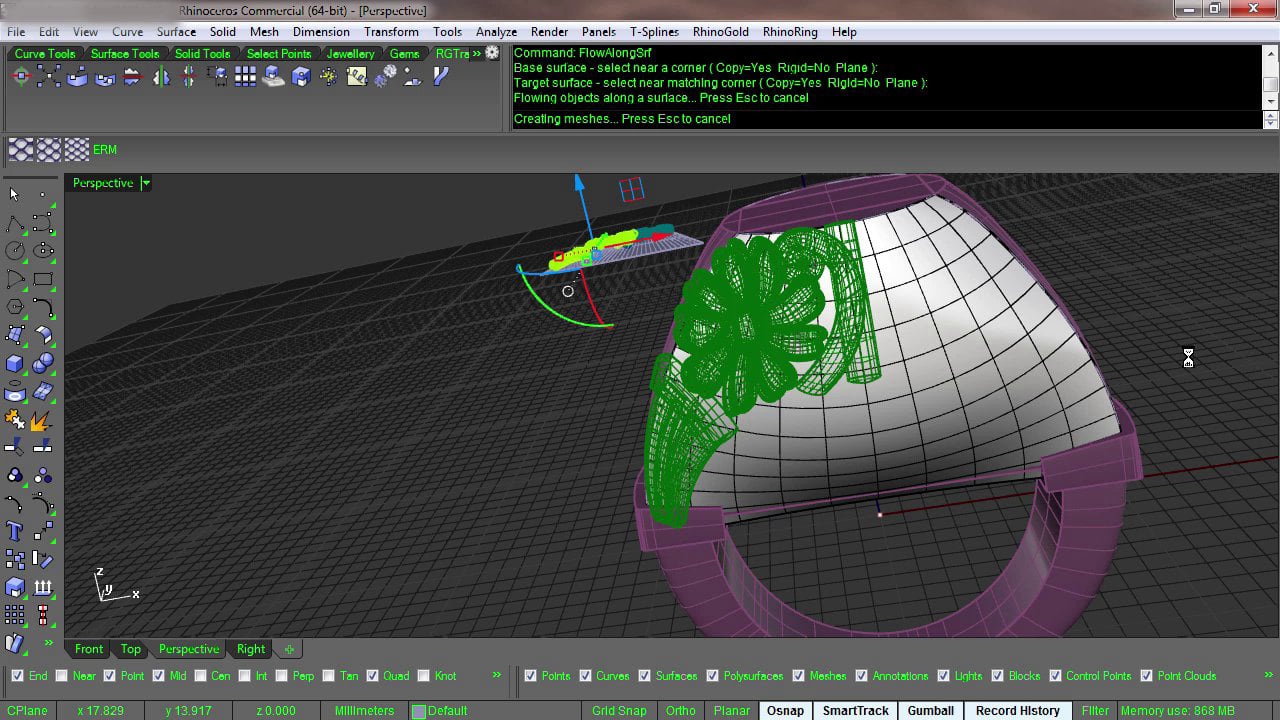

The customer is then notified of this change and shown a visual design nearly immediately. Working in the digital world with programs like computer aided design (CAD) not only cuts down on time, but on labor and materials costs as well. Now, designers don’t have to produce a physical sample of the design, just a digital rendering that looks like a photograph of the real thing.

Digital Manufacturing Leads to Internationalization of Brands

An exciting benefit of digital manufacturing is that it allows local manufacturers to go global relatively easily. Currently, only 12% of the international market is owned by large corporations, leaving plenty of opportunity for other designers in the jewelry manufacturing industry to reach markets outside of their own city. Many local brands that are attempting to expand have recently seen an increase in international sales of nearly 30%, thanks to technological advancements.

Personalized Jewelry

Personalized jewelry is steadily growing and attracting different types of consumers. Young teens and adults who wish to express themselves through their jewelry choices might wish for designs that are specific to their personality, while some people may want to own a piece of custom jewelry that they helped design to ensure that their jewelry is truly rare and unique. With digital manufacturing, designers can easily manufacture jewelry to meet the needs of all their clients.

Consumers also love branded jewelry from large brands that they’ve come to trust over the years—such as Tiffany’s, Cartier, and Pandora. Owning jewelry from these brands carries a certain prestige and exclusivity. Many popular clothing retailers have taken note of the rise in branded jewelry and have jumped into the jewelry industry with their own branded designs. Some of the biggest players in this area include Louis Vuitton, Dior, and Hermes. These brands identified an opportunity to capitalize on their names and have created an entirely new category in their business.

Online Sales Provide New Opportunity

Digital manufacturing creates the perfect opportunity for building an online business. As a jewelry designer or manufacturer, you no longer need to have a brick-and-mortar business in order to sell jewelry. You can simply set up an eCommerce website to showcase and sell your designs. You greatly lower your overhead costs and dismiss the need for a significant amount of capital and cash flow. While online stores decrease certain overhead costs, owning an eCommerce business still requires great dedication to marketing and content creation.

Another benefit of running an online store is that it eliminates the need for a physical display. Using renderings made in CAD ensures you don’t need to create models or samples for high-quality photos. Instead, you can create your jewelry on a computer and create images of it from any angle and in any material and color.

It’s also easier to display concept designs when you’re working digitally, as you don’t have to rely on pen and paper to convey your thoughts. Now you can mock up a design in as little as a few hours and provide a number of images that show your talent and creativity, as well as the kinds of designs you’re capable of producing.

Digital Manufacturing Allows for Intricate Designs

CAD and CAM (computer aided manufacturing) are sophisticated digital processes that make it easy for designers to produce more intricate designs. This technology is crucial for customer satisfaction and it provides clients with personalized jewelry pieces that fits their needs and desires.

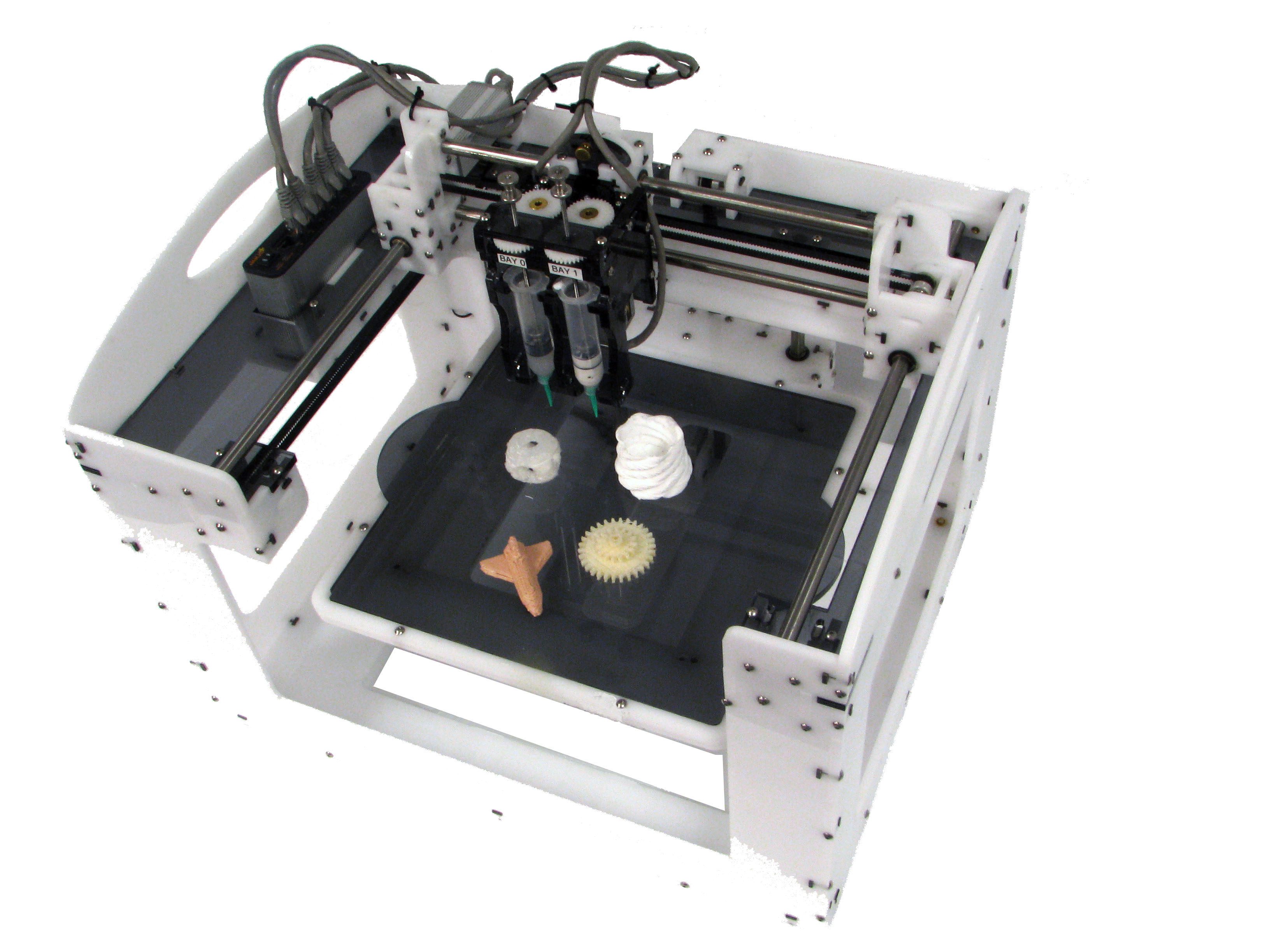

Clients simply need to verbalize what they want, and the designer can then use their computer to present them with a visual prototype. Once approved, the designer can create the physical mold by using evolved CAM processes, such as 3D printing. With countless hours and labor costs mitigated, jewelry designers and manufacturers have more freedom to create and customers can become more involved in the design process.

3D Printing

3D printing is a form of CAM that simplifies the creation process in the jewelry manufacturing industry. 3D printing eliminates the need to create molds and replicas by hand, and often eliminates the need to create a mold at all. Jewelry can be printed over the course of several hours, instead of several days, and immediately skip over to the appropriate finishing process. While many affordable printers only print in plastic, some high-end models can work with gold and other metals to create a finished piece right away.

Staying with the Times

Digital manufacturing presents countless opportunities for designers and manufacturers to do their job more efficiently. This has changed the industry in a profound way and has made it easier for the jewelry manufacturing industry to keep up with modern times.